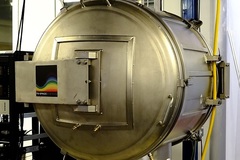

Our thermal vacuum chamber is regularly operated for monitored vacuum bakeout of test and flight hardware to ECSS-Q-ST-70-01. Flight hardware or sensitive samples can be loaded into the chamber from within Class 8 clean tent.

We also have an in-house FTIR facility for processing molecular contamination witness plates in accordance with ECSS-Q-ST-70-05C.

The chamber is fitted with a temperature controlled quartz crystal monitor (TCQCM) and a cold plate for contamination inspection and monitoring. TCQCM is analysed to determine bakeout completion as per ESA guidelines and ECSS-Q-ST-70-01.

The chamber can also be configured with a number of shrouds and thermal plates allowing thermal bakeout services up to +300 degrees C for a range of sample positions within the chamber e.g. flat plates, hanging samples, spools for thermocouples etc.

Pressure gauges, calibrated temperature data and TCQCM data is logged and provided to the customer along with TCQCM analysis if required. RGA (mass spectrometry) is also available on request.