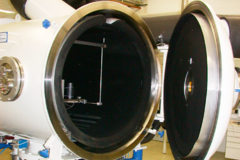

TVAC testing of flight hardware including bake-out.

We are also equipped with FTIR device for processing molecular contamination in accordance with ECSS-Q-ST-70-05C (direct or indirect method) and also device for processing particulate contamination per ECSS-Q-ST-70-50C.

All devices are situated in our ISO7 premise.

The chamber is equipped with TQCM. The bake-out is processed per ESA guidelines and per ECSS-Q-ST-70-01.

All control means like pressure gauge and thermocouples are regularly calibrated by independent body.

Available standards (e.g. ASTM, MIL):

ECSS-Q-ST-70-05C, ECSS-Q-ST-70-50C, ECSS-Q-ST-70-01

Features thermal:

Vacuum

Solar simulator

Thermal plate

Temperature controlled shroud

Specimen length [mm]:

700.0

Specimen width/dia [mm]:

500.0

Specimen height/thk [mm]:

500.0

Higher temperature [K]:

423.0

Lower temperature [K]:

123.0

Feedthroughs:

Thermocouple, RTD, Fluid, Power, (additional at request)

Data acquisition:

Temperature, pressure, QCM frequency

Vacuum limit [hPa] [mbar]:

below 1E-5

Project heritage:

EUCLID, MTG, Exomars

Cleanroom classes (ISO 14644-1):

ISO Class ≤5

ISO Class 6

ISO Class 7

ISO Class 8

ISO Class 9

Certification:

ISO/IEC 17025

ISO 9001

AS/EN/JISQ 9100

Keywords:

TVAC, thermal vacuum, qualification, bakeout, cycling, thermal balance, Frentech Aerospace, Brno, Czech