The XVC test facility was developed for the exposure of components to thermal vacuum conditions, representing space environment in open space and sun exposure. Furthermore, the thermal vacuum bakeout and the thermal vacuum cycling of flight hardware are key applications for this test facility.

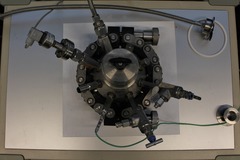

The vacuum chamber is made of stainless steel and offers an inner space of approx. 1,500 mm in width, 1,500 mm in height, and a length of 2,000 mm (volume: approx. 4,5 m³). Therefore, the test facility is suitable for testing larger sub-elements and components.

The temperature of the hardware under investigation is adjusted by means of temperature-controlled copper plate(s) mounted inside the vacuum chamber, and by additional wall/door/ceiling heaters. Process plates are heated electrically, the cooling is performed by liquid nitrogen (LN2: T = -196 °C).

The XVC test rig is attached to a clean room classified as ISO7.

- Heating / Cooling rate up to 3-4 K/min

- Maximum operating temperature 200 °C

- Minimum operating temperature -185 °C in vacuum

- Atmosphere: Vacuum 1e-7 mbar, non corrosive gas (N2, CO2, Ar,...) up to ambient pressure

- Various copper shields for improved thermal homogeneity available

- Up to 6 heating/cooling plates may be used with 3 plates mounted on the lower side, acting as sample support plates, and 3 smaller plates of 1,000x700 mm² each on the upper side for providing a thermal shroud

- A total process plate area of up to 1,300x1,800 mm² is available.

Aerospace & Advanced Composites GmbH - your highly experienced partner in material testing and development for space, aerospace and terrestrial applications.