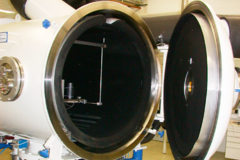

The LVC test facility simulates thermal vacuum conditions, e.g. space environment in open space and sun exposure. The vacuum chamber offers an inner diameter of 1,500 mm and a height of 1,500 mm (volume: approx. 1.5 m³).

The temperature of the hardware under investigation is adjusted by means of a copper process plate mounted inside the vacuum chamber. The plate is heated electrically, the cooling is performed by liquid nitrogen (LN2: T = -196 °C). General specifications of this plate are:

- Available dimensions: 1000x700 mm², 500x500 mm², extension plates 1,000x1,000 mm²

- Heating / Cooling rate up to 5-6 K/min

- Maximum operating temperature +250 °C (short time), +200 °C (continuous)

- Minimum operating temperature -185 °C in vacuum

- Atmosphere: Vacuum 1e-6 mbar, non corrosive gas (N2, CO2, Ar,...) up to ambient pressure

- Various copper shields for improved thermal homogeneity available

The LVC test rig is positioned in a “visible clean” laboratory clean environment next to an ISO7 clean room that may be used for sample preparation.

Aerospace & Advanced Composites GmbH - your highly experienced partner in material testing and development for space, aerospace and terrestrial applications.