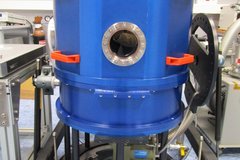

The aim of the TVC test facility is the simulation of thermal vacuum conditions (e.g. space environment in open space and sun exposure). The vacuum chamber is made of stainless steel and offers an inner diameter of 880 mm and a length of 1,200 mm (volume: approx. 0.7 m³).

The temperature of the hardware under investigation is adjusted by means of copper process plate(s) mounted inside the vacuum chamber, and – if required – by heating the chamber wall. Process plates are heated electrically, the cooling is performed by liquid nitrogen (LN2: T = -196 °C). General specifications of this plate type are:

- Available dimensions: 1,000x700 mm², 500x500 mm².

- Maximum heating / cooling rate 5-6 K/min

- Maximum operating temperature +250 °C (short time), +200 °C (continuous)

- Maximum cooling rate ~ 5-6 K/min

- Minimum operating temperature -185 °C in vacuum

- Atmosphere: Vacuum 5e-7 mbar, non corrosive gas (N2, CO2, Ar,...) up to ambient pressure

The TVC test rig is attached to a clean room classified as ISO7.

Aerospace & Advanced Composites GmbH - your highly experienced partner in material testing and development for space, aerospace and terrestrial applications.