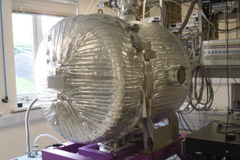

The thermal vacuum test facility will simulate the environmental and thermal conditions in space. It is equipped with a black shroud and a hot-cold plate controlled at the same temperature. The average temperature change rate is 1.5°C per minute.

The data acquisition system can handle up to 12 thermal sensors (Pt100) at the moment and can be updated to 32 thermal sensors with prior notice. A special Safety Rack protects the test article during automatic thermal cycling mode, ensuring that the products are kept safe during testing.

The thermal vacuum chamber is small and therefore more cost-effective than other bigger chambers.

Type:

Service

Features thermal:

Vacuum

Solar simulator

Thermal plate

Temperature controlled shroud

Specimen length [mm]:

580.0

Specimen width/dia [mm]:

580.0

Specimen height/thk [mm]:

250.0

Higher temperature [K]:

398.0

Lower temperature [K]:

210.0

Temperature change rate [±K/min]:

1.5

Feedthroughs:

2x D-Sub 50, 3x D-Sub 15

Data acquisition:

Temperature: 12x Pt100; Pressure Gauge: 10^9 - 100 mbar, Voltage: +/-10

Vacuum limit [hPa] [mbar]:

10^6

Project heritage:

This facility is used for the test of space equipment as well as of other highly sensitive industrial products and prototypes.

Cleanroom classes (ISO 14644-1):

ISO Class ≤5

ISO Class 6

ISO Class 7

ISO Class 8

ISO Class 9

Certification:

ISO/IEC 17025

ISO 9001

AS/EN/JISQ 9100

Keywords:

TVAC, TV test, thermal vacuum cycling, thermal cycling