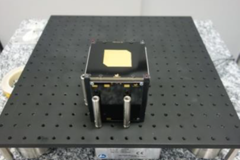

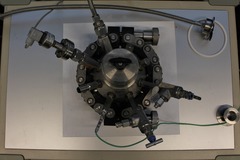

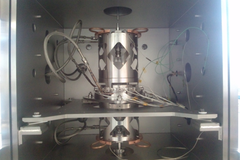

Ball bearings can be tested in a wide range of parameters and environments at AAC. For testing over wide temperatures but lower testing durations the devices “SALOTTE” and “HADES” are used. For very long term testing from RT to +300°C the “BBT” is used. The “BBT2-frames” allow to test also very small amplitudes (swivelling). In addition to those devices, two more vacuum tribometers can be adapted to test ball bearings: the Cryo-Tribometer (offering RT down to 4K) and the High-Temperature-Vacuum Tribometer (offering RT to +700°C).

These facilities enable to measure the torque of ball bearings from air to high vacuum. Environments vary from vacuum, non-aggressive gases (e.g. He, CO2) under controllable pressures (e.g. to simulate Martian environment) or to air with controlled humidity.

Measurement of:

• Torque

• Angle

• Environmental Data

• Optional: residual gas analysis (mass spectrometer of outgassing particles)

Parameters:

• Standard: -170°C to +250°C, cryogenic (4K) and high temperature (700°C) on request

• Oscillating (incl. swivelling) and unidirectional movement

• Speed from 0.1 to 1000 RPM (swivelling up to 60Hz)

• Environment: air, gas, vacuum

• Data acquisition up to 10kHz

• Ball bearings in paired or single setup

Aerospace & Advanced Composites GmbH - your highly experienced partner in material testing and development for space, aerospace and terrestrial applications.