Failure analysis is a post mortem examination of failed devices employing, as required, electrical measurements and many of the advanced techniques of physics, metallurgy, and chemistry in order to confirm the reported failure mode and identify the responsible failure mechanism: ESD, EOS, electro-migration, purple plague, dendritic growth, corrosion, whiskers, ..., etc.

The failure analysis sequence must be reviewed and tailored on a case by case basis. A test flow reference could be the following:

(a) External Examination.

(b) Electrical Verification.

(c) X-Ray Radiography.

(d) Leak Test.

(e) PIND Test.

(f) External Package Cleaning. Vacuum Baking (If needed).

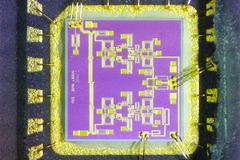

(g) Decapsulation and Internal Examination.

(h) Additional Electrical Measurements. Multipoint Probe.

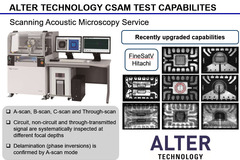

(i) Optional Measurements (as needed).

▪ Total Device Cross Section.

▪ Residual Gas Analysis.

▪ Infrared Scanning.

▪ SEM, FIB,…, etc.