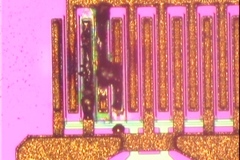

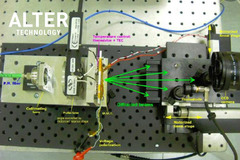

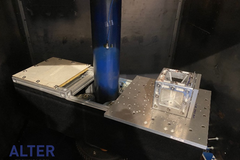

TMA of Plastic encapsulated microelectronic and other electronic materials (PCB,...) are basic techniques to determine materials characteristics and final device performances/reliability.

The TMA (The thermomechanical analysis) support avoiding problems at the design and fabrication stages, and also foresee anomalies related to the deformation of materials with temperature and the related failure mechanims. Thus, this is a very effective tool to disclose and screen out possible reliability concerns related to the thermo-mechanical integrity and stability of the devices, being a perfect tool to assess plastic COTS devices.

Type:

Service

Available standards (e.g. ASTM, MIL):

• ASTM E831. “Standard Test Method for Linear Thermal Expansion of Solid Materials by Thermomechanical Analysis”. • ASTM E1545. “Standard Test Method for the Glass Transition Temperature by Thermomechanical Analysis”. • ASTM D696. “Standard Test Method for Coefficient of Linear Thermal Expansion of Plastics Between −30°C and 30°C with a Vitreous Silica Dilatometer”. • ASTM D3386. “Standard Test Method for Coefficient of Linear Thermal Expansion of Electrical Insulating Materials”. • ISO 11359: Parts 1-3. “Plastics – Thermomechanical analysis (TMA)” – (Part 1. “General principles”, Part 2. “Determination of coefficient of linear thermal expansion and glass transition temperature”, Part 3. “Determination of penetration temperature”.)

Certification:

ISO/IEC 17025

ISO 9001

AS/EN/JISQ 9100

Keywords:

TMA, COTS, CTE, PEM, Tg, CSAM