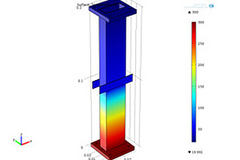

Small Cryogenic Thermal Vacuum Cycling - Test Dewar n°2

Callisto's test service provides a flexible solution to evaluate the performance of components at cryo temperatures, priced on a per-test basis and thereby minimising cost for the customer. The comprehensive service includes:

- Test planning, feasibility assessment, evaluation of test requirements and definition of needs for test jigs, interface adapters etc,

- Provision of any necessary test jigs, adapters interface cables or transmission lines,

- Installation of components to be tested,

- Operation of cryogenic test Dewar and associated monitoring Equipment,

- Conducting or assisting in running measurements on components,

- RF instruments (Vector network analyser operating up to 40GHz, Spectrum Analyser, etc...)

Examples of components requiring testing are listed below, spanning the radio-astronomy, earth observation satellite, air-borne imaging systems, medical imaging and computing sectors:

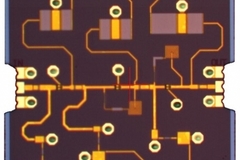

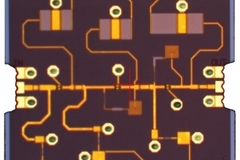

- Ultra-low noise RF LNAs, mixers, filters, connectors and components,

- Superconductor (HTS or LTS) components,

- Infra-red detector components,

- On-board space craft instrument components (optical, radar and electrical),

- Any electrical or mechanical component destined for use in cryogenic assemblies (e.g. imaging and medical instruments).

- Mechanical assemblies such as bonded parts.