It is of crucial importance to design aerospace products taking into account the ability to withstand mechanical shocks. In this field, KRP offers a complete support from design to verification. Prediction, testing, and damping solutions are the key capabilities of KRP’s portfolio regarding mechanical shock.

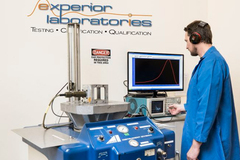

In the KRP shock test facility, shocks are produced by mechanical impact on a resonant plate (e.g. 1000x1000x20 mm3 Aluminium). The mechanical impacts are performed in different possible ways to cover a wide range of shock profiles. E.g. dropping-mass using steel spheres or a hammer are mostly used to tune far field shock, a pyro actuated gun is used to achieve near field shocks. To achieve the required impact energy, tuning is done by mass dummies, providing repeatability of the shock.

Type:

Service

Available standards (e.g. ASTM, MIL):

ECSS

Features mechanical:

Sine

Random

Shock

Static load

Micro vibration

Acoustic

Specimen length [mm]:

1000.0

Specimen width/dia [mm]:

1000.0

Specimen height/thk [mm]:

500.0

Mass max. [kg]:

50.0

Frequency min. [Hz]:

100.0

Frequency max. [Hz]:

5000

Acceleration shock [g]:

20000

Data acquisition:

100kHz per chanel, up to 24 chanels

Project heritage:

ExoMars, EnMAP, MTG, VEGA, HDRMs - shock testing and shock measurement

Certification:

ISO/IEC 17025

ISO 9001

AS/EN/JISQ 9100

Keywords:

KRP Mechatec GmbH, mechanical shock testing