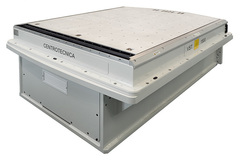

Rigid 5-axis machine, especially developed for the pressing tools, injection moulds and forging dies.

• 5-axis machining on single clamping with 2-axis milling head.

• Upper gantry portal machine for high dynamics and accuracy.

• Unique closed design of the cross-beam and cross- slide (box-in-box design) with internal,

quadruple- guided, ram-type milling unit (Y- and Z-axis).

• Constantly perfect cutting results thanks to unique thermo-symmetric design.

• Stationary work piece for the highest surface qualities.

• Very compact machine with large working area utilizing minimal floor-space.

• High productivity - roughing and finishing operations in one set-up.

Table size

• 4.000 x 2.800 mm

• 1 milling head

• Max. table load 7t/m2

X-Y-Z travels

• 3.500 x 2.500 x 1.500 mm

Milling spindle

• HSK A-100

• 50/40 kW, 314/248 Nm (40%/100%)

• 10 - 12.000 RPM

Workpiece weight

• According to the crane load capacity max. 32t