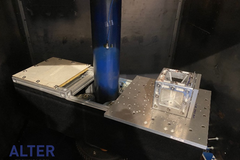

Is a systematic, logical, detailed examination of EEE parts at various stages of physical disassembly. This activity is performed in order to verify that the manufactured lot quality is in accordance with the detailed specification and project requirements.

In a DPA parts are examined for a wide variety of design, manufacturing, workmanship, and processing problems which may not observed in previous inspection stages.

DPA is conducted on samples randomly selected from the lot and consists of a series of various tests and inspections depending on the component type and package style. Among others, typical test are::

- X-ray Examination

- External Visual Inspection

- Seal tests (Fine& Gross leaks)

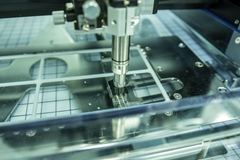

- Particle Impact Noise Detection (P.I.N.D)

- Solderability

- Internal Visual Inspection

- Bond Pull

- Scanning Electron Microscope (SEM)

- Die Shear

Type:

Service

Available standards (e.g. ASTM, MIL):

ESCC - "Destructive Physical Analysis", S‐311‐M‐70 "GFSC Specification for the Performance of DPA", SSQ 25000 "DPA Testing Specification for the SSP", MIL‐STD‐1580 "DPA for EEE Parts", MIL‐STD‐883 "Test Method 5009 DPA", MIL‐STD‐750 "Test Method 2101, DPA Procedure for Diodes", NASA-PEM‐INST‐001 "Section 5 DPA for PEMS".

Certification:

ISO/IEC 17025

ISO 9001

AS/EN/JISQ 9100

Keywords:

DPA, Alter Technology