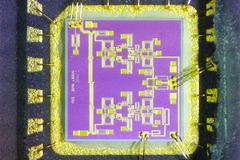

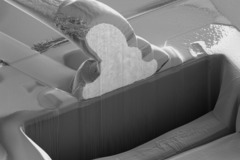

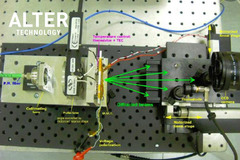

Scanning Acoustic Microscopy (SAM), a consolidated and recognized tool for quality control, inspection and failure analysis of microelectronic components and materials. This inspection technique is routinely used for the non-destructive detection of internal anomalies (cracks, voids and delamination, porosity, hermeticity issues…).

Capabilities:

• Scanning Acoustic Microscopy. Confocal inspection.

• Multi-focal imaging.

• Thought transmission ultrasound inspection.

• A-scan, peak amplitude and phase inversion analyses.

• Detection of micrometric features of submicrometric

thickness.

• Depth mapping.

• Non-destructive visual crossectioning.

• Fourier transform data treatment.

• Post-inspection moisture removal.

Used Standards and Test methods:

• Plastic encapsulated systems

PC/JEDEC J-STD-020E (Moisture Sensitivity level)

IPC/JEDEC J-STD-035

ESCC25200 (Space level)

NASA PEM-INST-001 (Space level)

MIL-STD-1580 (Military level)

• Chips on board and post-soldering verification

GEIA-STD-0006

• Ceramic capacitors

MIL-PRF-123 , MIL-PRF-31033, MIL-PRF-49470

• Hermetic packages

Die attach and lid-seal inspection

• ...., etc.