The main area of our activities in the field of composite technologies is:

• provision of testing services,

• providing new manufacturing technologies for the industry,

• conducting research and development projects.

We have a certified composite materials testing laboratory and advanced equipment for the production of this type of structures.

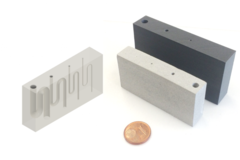

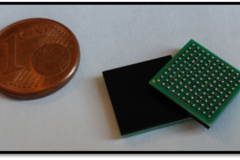

We have advanced technological facilities used for testing of the new technologies and for the production of prototype composite structures. As part of the research work for the designed construction solutions, manufacturing technologies are developed, and the produced prototypes of the structures are subjected to further tests.

We design and manufacture test instruments tailored to the individual needs of our Customers.

We conduct research in the field of repairing aircraft composite structures. We develop repair technologies for aircraft structures made of pre-impregnates and thermoplastic composites, as well as repair technologies adapted to limited service back-up facilities.

Our offer includes the following services:

• Development of a damage detection method

Development of procedures for detecting damage to composite structures during operation based on visual inspection and non-destructive testing.

• Composite structures repairs technologies

Designing the repair process taking into account:

- type of material,

- structure configuration,

- access to the repair place,

- allowable curing temperature.

• Development of a repair technology with a patch made of pre-impregnates, already hardened or hardened on the repaired structure.

The institute offers the following services:

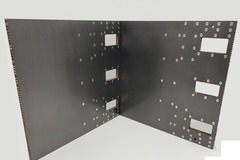

• Defining the procedures for recording production and quality control activities for each manufacturing stage of composite aerospace structures.

• Defining the scope of destructive testing – “witness” samples.

• Geometric control of tooling and structures using a 3D laser scanner.

• Ultrasonic testing of composite structures using phased array (C-scan) conventional technique.

• Low-frequency testing of composite structures by bond testing (C-scan) technique, tap testing (woodpecker, hammer).

• Thermographic testing of composite structures (active thermography).

• Visual inspection of composite structures.

• Comprehensive development of methodologies for non-destructive testing of composite structures.

• Calibration plate design.

• Detection of defects like: delamination, cracks, porosity, foreign bodies.

• Quality control

All manufacturing work is subject to quality control. The quality control process includes documentation and material control, process control and product control. Scope of the quality control is adjusted each time to the specificity of the work in progress.

Learn more: https://ilot.lukasiewicz.gov.pl/en/offer/composite-structures/