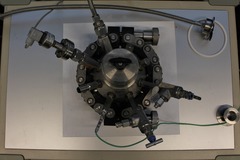

Sliprings are a common building block to transfer power and electric signals from stationary structures to rotating structures. The characterization of sliprings in terms of noise, resistance, friction, wear, stress relaxation of brushes, … can be done at AAC’s Salotte2 facility.

One ring with up to 4 brushes can be tested from ambient environment, gaseous environment to thermal vacuum. Friction- and load force for each brush is measured. The voltage drop on the slipring and the transferred current are measured with an accuracy and speed so that micro interruptions of down to 1ms can be detected. Post-test analysis of ring and brushes with SEM / EDX shows the wear and its mechanism. Different movement and thermal profiles can be done to simulate lifecycles of space-missions.

The setup can be adapted to take up potentiometers or different kinds of sliprings. Additional measurements like temperature of brush with IR camera even in vacuum, arcing, stress relaxation of preload in thermal environment are available. Beside standardized tests, AAC aims to adapt the test method and test setup as close as possible to your needs.

Aerospace & Advanced Composites GmbH - your highly experienced partner in material testing and development for space, aerospace and terrestrial applications.