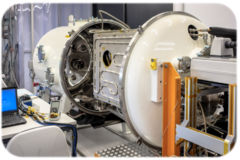

Micos operates a Thermal Vacuum Chamber equipped with a thermally controlled plate reconfigurable for customer projects. The thermal environment can be controlled by up to 3 independent Julabo units/circuits to 10 mK stability. Traceable to ITS90, SPRT sensors are available, along with a ASL bridge for 1 ppm accurate resistance measurements, at up to 10 channels. PRT-s and thermalized NI bay are also available for over 20 channels. The outgassing within the TVAC is monitored by of RGA (MKS e-vision 2, 200 amu) and QCM (QCM Research MK10).

Available standards (e.g. ASTM, MIL):

ITS90

Features thermal:

Vacuum

Solar simulator

Thermal plate

Temperature controlled shroud

Specimen length [mm]:

820.0

Specimen width/dia [mm]:

590.0

Specimen height/thk [mm]:

765.0

Mass max. [kg]:

200.0

Higher temperature [K]:

423.0

Lower temperature [K]:

233.0

Temperature change rate [±K/min]:

5.0

Feedthroughs:

electrical, fluid, optical/IR window

Data acquisition:

ASL DC bridge, 10ch, 25, 100, 1000, 10k Ohm ref., NI bays, thermalized, calibrated, Julabo external sensors PT100

Vacuum limit [hPa] [mbar]:

1E-7 mbar

Project heritage:

MTG

Cleanroom classes (ISO 14644-1):

ISO Class ≤5

ISO Class 6

ISO Class 7

ISO Class 8

ISO Class 9

Certification:

ISO/IEC 17025

ISO 9001

AS/EN/JISQ 9100

Keywords:

thermal vacuum, TVAC, Julabo, SPRT, bridge, RGA, QCM