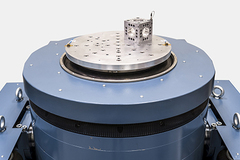

Experior can conduct cyclic corrosion testing (CCT) to determine cosmetic or corrosion performance of paints, coatings, and other protectants. With an interior cabinet size of 48 x 33 x 24 inches, our industrial test chamber can immerse, spray or fog many components and devices. The temperature can go up to and maintain 60 deg celsius, while the relative humidity range goes from ambient to 100%. The test time can be customer specified ranging from minutes to failure testing (days or months).

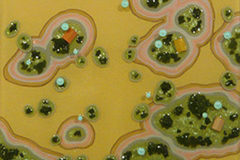

A wide range of industry standards, requirements, and performance specifications can be conducted at our test lab. For example, SAE International issued J2234 for the automotive industry. In this standard, products are subjected to either 5 or 7 days of corrosion cycles. To simulated accelerated corrosion, there are three stages of testing: humid stage, salt application stage, and dry stage. The salt is combined chemical mixture of NaCl, CaCl2, NaHCO3. The before and after visual analysis is compared to ensure no corrosion exists on the coating.

A well-known standard issued by the American Society for Testing and Materials (ASTM) is G85 Annex 5, which sets forth conditions for dilute electrolyte cyclic fog/dry test. This test, popular for paints on steel, uses sodium chloride and ammonium as the electrolyte solution instead of a traditional salt fog. Products are subjected to 1-hour wet and 1-hour dry cycles.