Nitrexo standardizes its processes for conducting thermal analyses and makes them available to thermal engineers. Through the proprietary software the company is developing, thermal engineers from around the world can actively engage with each other.

This digital engineer allows thermal engineers to ask questions, provide comments to other parties, and share their knowledge and expertise. This in turn leads to the betterment of thermal engineering communities in particular and the space industry in general.

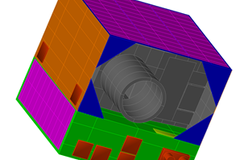

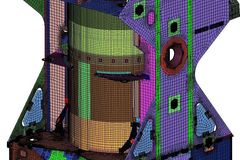

At Nitrexo, traditional thermal engineering concepts and principles are integrated with the latest digital technology. The company ensures that its clients receive thermal analysis reports. It also creates 3D models and extensively uses ESATAN-TMS®, a tool to accurately calculate heat transfer systems.

These thermal models improve the productivity of thermal engineers and increase companies’ service and product efficiency. The use of precise and standard models in analytical and testing activities also minimize the risks and errors, allowing companies to complete projects in less time and at reduced costs.

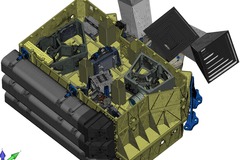

With specializations in payloads, sub-systems, system level, solar panels, mechanisms, instruments, antennas, sensors, mirrors, electronics, optoelectronics devices for satellites, rockets, microelectronic components, and ground support equipment, Nitrexo has completed projects for the European Space Agency and QinetiQ.

Even the best mechanical engineers need help in solving some of the most complex issues in the spacecraft industry. Nitrexo offers the ideal and cost-effective solution to address the growing need for critical technologies that can boost a company’s value.

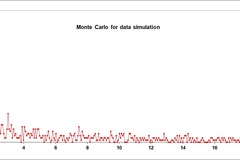

From conducting conceptual studies and developing 3D thermal models to conducting various analyses (e.g. stress, optomechanical, numerical simulations, etc.), Nitrexo is a company that delivers innovative and dynamic software solutions to help space and aeronautic companies stay ahead of the curve.