The ZARM vibration test lab enables fatigue testing for a variety of technical applications. We are specialists in the testing of aerospace components and scientific test setups. Our test lab makes it possible to test devices not only while they are in full operation but also under exposure to additional endurance test loads such as temperature cycling, icing, pressure surge, etc..

Technical Description:

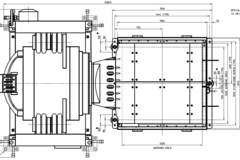

The vibration test facility consists of a V875 shaker and a HBT 600 slip table, mounted on a common base structure. This arrangement allows the use of the shaker in vertical axis or rotated to horizontal axis, in the so-called slip table mode.

Payload Size

According to typical international aerospace vibration test standards, the maximum suitable payload weight of our shaker is 180 kg, although heavier objects can still be tested when using lower test loads. The maximum size of the payload should however not exceed the mounting platform area of 600 x 600 millimeter. But whatever your payload looks like, we will find a solution to securely attach your product to the shaker – either with one of the many adapters we have in stock, or by designing a new adapter in the ZARM workshop.

Measuring

Measurement amplifiers are located close to the shaker, providing short sensor lines resulting in a very high signal quality. Our high quality test and measurement equipment is continuously calibrated and meets international standards.

Handling

For easy and safe handling of heavy test components a portal crane can access every corner of the workspace.

Environment

The shaker operating room is fully air-conditioned. ZARM also provides an additional class 100,000 clean room for preparation, inspection, system checks, etc. of sensitive test objects.

Control Room

Customers have the chance to observe the shaker test from the nearby control room through a bulletproof window. The shaker unit is cushioned by air isolation mounts to avoid vibration damage to the building. All rooms belonging to the vibration test lab are equipped with noise absorbing walls and double door gates.

Technical Data:

• Long Stroke Shaker: LDS V875 HBT 600 Vibration Test Combination

• frequency range: 5 - 3000 Hz

• max. load: 600 kg (vertical operation), 5000 kg (horizontal operation)

• max. useful load: 180 kg

• max. force vector: 35.6 kN (sine, random), 106.8 kN (shock)

• max. acceleration: 110 g (sine), 73.5 g rms (random), 220 g (shock)

• max. velocity: 1.8 m/s (sine, random), 2.5 m/s (shock)

• max. stroke: 50.8 mm (peak-peak)

• mounting interfaces:

horizontal slip table (600 mm x 700 mm, grid = 100 mm, M8)

horizontal base plate (600 mm x 600 mm, grid = 40 mm, M8)

vertical base plate (Ø 450 mm, grid = 50 mm, M8)

vertical base plate (octagon, width 544 mm, grid = 40 mm, M8)

vertical head expander (600 mm x 600 mm, grid = 50 mm, M8)

• Control and Measurement System m+p:

VibControl/VcpNT - VibRunner24

General Features:

• 16 differential measurement channels

• voltage, ICP and TEDS support

• various protection / shutdown functions

• channel number update on request

Standard Test Loads:

• random

• sine

• classical shock

• transient capture

• additional test loads on request