SMAC develops and designs tailor-made solutions based on elastomeric materials to protect your equipment from shock and vibration. SMAC relies on a dedicated design office (mechanical, material) and on the other hand on a test laboratory to test your equipment as realistically as possible.

Such organization allows us to offer support solutions adapted to your needs according to different perimeters:

- Vibration tests in order to characterize the modal spectrum of your systems,

- Anti-vibration solution coupled with vibration performance measurements,

Our engineering team and qualified technicians will bring their know-how to support your projects with the greatest rigor and within the proposed deadlines.

We offer a variety of tests such as thermal ageing, quasi-static, dynamics, vibration, shock and modal analysis.

Our test facility is composed of :

- Tensile/compression machines (10 kN and 20 kN)

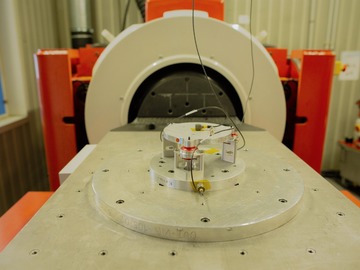

- 60 kN Electrodynamic shaker equipped with a vibrating table and 16 frequency measurement channels. The tests can be carried out at controlled temperature (between -55 ° C and +90 ° C)

- 24 kN Electrodynamic shaker with 8 measurement channels and equipped with a thermal chamber (5 ° C to 35 ° C)

- 40 N Electrodynamic shaker for modal analyzes (temperature measurement from -30 ° C to 60 ° C) with 4 measurement channels

- A pyrotechnic type shock-generating device ("Ringing plate")

- A high sensitivity dynamometer for microvibration measurement

- Climatic chambers (with or without primary void)

Moreover we also have various academic partners in order to carry out very specific physicochemical tests (DMA, DSC, ATG, IRTF, NMR, GC-MS, …).

Our laboratory is ISO 9100 certified but all business sectors (automotive, composite, rail, metals, medical, etc.) will be treated with the same sensitivity and quality.

5 open listings

No followed people

No reviews