Additive manufacturing allows the creation of complex geometries and strong and lightweight parts in a cost-effective way. This technology is especially useful for rocket engines development for in space propulsion.

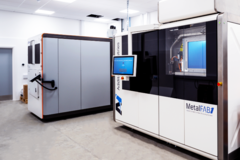

The MetalFab 1 is located at the IOSM Facility in Westcott Venture Park. This technology is available to companies on a pay-as-you-go basis, working with the Catapult’s Manufacturing for Space team.

The specific technology of the MetalFAB is Laser Powder Bed Fusion (LPBF). It has a large build platform with net build envelope of 420 x 420 x 400 mm. The material that is currently being used is Inconel 718 with a layer thickness of 40 μm. It has 2 lasers of 500W and has an accuracy of ~0.05mm. It is possible to remotely access and monitor the printing processes with continuous video feed.

Watch our Manufacturing video here: https://www.youtube.com/watch?v=iHKQ9OXeeP8

Type:

Service

Keywords:

Metal Additive Manufacturing, MetalFab, Additive Manufacturing, propulsion, rocket engines