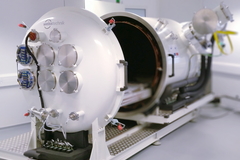

Bake Out facility is installed in a permanent ISO8 cleanroom. The chamber is equipped with a Thermolectric Quartz Crystal Microbalance (TQCM) to monitor outgassing. TQCM data are processed to validate bake out completion as per ESA guidelines and ECSS-Q-ST-70-01C. A liquid nitrogen temperature cold trap will limit outgassing redistibution during the bake out process. Particulate and molecular contamination witnesses are available on request.

To optmize harnesses and MLI blankets outgassing, the chamber is fitted with a shelves modular system.

Chamber repressurization can be controlled to fulfill ESA's recommendation of a <20mbar/min slope.

Pressure, temperature and TQCM data and analysis are provided to customer.

Features thermal:

Vacuum

Solar simulator

Thermal plate

Temperature controlled shroud

Specimen length [mm]:

1000.0

Specimen width/dia [mm]:

550.0

Specimen height/thk [mm]:

500.0

Higher temperature [K]:

453.0

Lower temperature [K]:

293.0

Temperature change rate [±K/min]:

2.0

Feedthroughs:

18 Channels K Type Thermocouples, D-Sub 25pts M/F

Data acquisition:

Temperature, Pressure, QCM frequency

Vacuum limit [hPa] [mbar]:

>1e-7

Cleanroom classes (ISO 14644-1):

ISO Class ≤5

ISO Class 6

ISO Class 7

ISO Class 8

ISO Class 9

Certification:

ISO/IEC 17025

ISO 9001

AS/EN/JISQ 9100

Keywords:

Bake Out, Vacuum outgassing, TQCM monitoring, MECANO ID, mecano id,