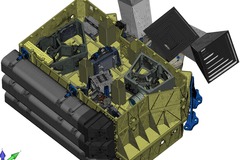

Madrid Space offers you a complete support on design of lightweight metallic and composite structures, including optimized components for Additive Manufacturing. From conceptual and preliminary design phases, through detailed design models, up to ready-to-manufacturing parts, our capabilities cover the entire design and manufacturing cycle. In such a way, we are able to deliver turnkey parts for the most demanding sectors: space, aerospace, science…:

• Definition of conceptual/preliminary proposals to fulfil the requirements defined by our clients, from the design point of view itself, integration, manufacturing, assembling, costs, reparability and so on.

• Detailed definition of designs, including 3D models, 2D drawings (manufacturing and assembly), Part-Lists; and all the documentation required by our clients according to their internal quality standards, including applicable aerospace regulations.

• Analysis and definition of all the tolerances involved, including control of I/F points.

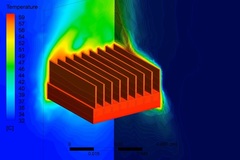

• Compatibility and integration of systems and thermal components.

• Management of Product Structure, 3D Mock-Up and control of configuration.

• Concurrent engineering, involving teams of Structural analysis, Manufacturing and Providers.

• Extensive experience with Catia® V5 and Hyperworks® packs for optimization.

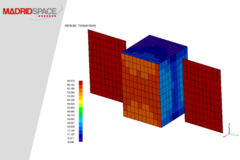

In terms of analysis, our expertise covers:

• Linear Static analysis: hand calculation and FEM analysis for sizing and justification.

• Non-Linear Static analysis: contacts, large displacements.

• Buckling

• Modal Analysis

• Dynamic Analysis for Space Structures (Sine, random, spectrum, transient)

• Experience with Nastran/Patran, Hyperworks, Abaqus