Compatibility testing is basically performed on basis of ECSS-E-ST-35-10C.

e.g. Screening tests (6.2.1.):

Exposure of samples to the fluid (MMH, UDMH, Hydrazine, NTO, MON-1, MON-3) for two hours at ambient conditions and obtain of any visible effects or changes in either the material or the fluids will be done by photography of the samples before and after immersion an the liquids during the test.

Some of the defined tests cannot be performed in in our own lab but we can find possibilities for sub contraction.

We can realize Temperatures up to 55°C and pressures up to 20 barg.

Immersion times up to 60 days have been performed in the past.

A detailed list of our activities:

Screening test (6.2.1)

• Pictures before/after compatibility Test

• Daily observation of samples – any visible effects noticeable?

• Short report

Test (6.2.2)

• Preparation of the Sample containers – cleanliness; pressure test (leak tightness verification)

1 container for each sample + 1 container without sample (for reference based on ECSS) n+1 container

• Organization; preparation; calibration of sensor equipment (pressure and temperature) for all containers

• Sample preparation – before : conditioning of the samples; Mass; Dimensions; pictures

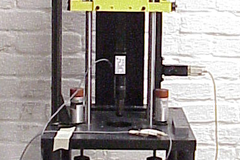

• Determination of mechanical attributes – before (hardness; pulling tests) not possible in LAM

• Determination of NVRs – before

• Putting samples into containers/fluids and test start

• Daily observation of each sample – 60 days -TBC

• Taking out samples of the containers

• Decontamination of samples

• Determination of mechanical attributes - after (hardness; pulling tests) not possible in LAM

• Determination of NVRs – after (optional: a complete analysis of the fluid of each container)

• Documentation (one report for each Project)

• Provision of Fluids

• Disposal of waste fluids