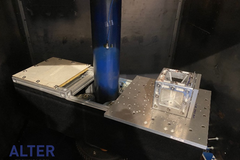

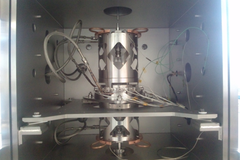

Novel materials undergo rigorous autoclave testing to assess their resilience to physical, chemical, and environmental challenges. This method involves exposing materials to controlled combinations of liquid, temperature, pressure, and atmospheric conditions to simulate real-world scenarios. Autoclave testing is effective for rapidly evaluating resistance to corrosion, coating degradation, environmental reactions, and establishing application limits. Adjustable parameters, including water vapor resistance and chemical resilience, provide insights into a material's performance under diverse stressors.

Testing according to Standards:

• ASTM G31-21

• G11-19, G46-2013

• G48-2015

• G170-2012

• NACE Standard TM0185-2006 (No. 21217)

• ISO 6872:2015

Volume (mL): 4000

Pressure (bars): 150

Working Temperature (°C): 200

Inner Dimension (mm): Ø 125, H: 380

Liquid Phase: Water, glycols, alcohols, etc

Gas: Air, Ar, N2, O2

Aerospace & Advanced Composites GmbH - your highly experienced partner in material testing and development for space, aerospace and terrestrial applications.