A pyroshock is the structural response of the test object to a shock load of a pyrotechnical process. Possible damaging effects of pyroshocks are:

- Cracks and fraction in crystals, ceramics, glass shrouds, soldering joints, electric wires, sealings and epoxy resins

- Deflection of small and light-weight structures

- Destruction or failure of electric relays and switches

- Damaging, especially on alignments, optic and micro-mechanic parts

- Short circuits caused by detaching and transporting of conductive particles

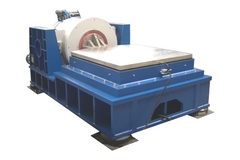

Pyroshock

· loads simulated by impact shocks

· shock by means of bolt driving tool

Classic Shock

· impulse hammer test facility

· hammer transfers the kinetic energy to the test item

· high degree of flexibility by varying the point of application and intensity of shocks

· measurement of shock input in 3 axes and Response

MIL 883 Unit Tests

Transportation Tests

Automotive Tests

Standard and Customer Requirements

Available standards (e.g. ASTM, MIL):

MIL 883

Features mechanical:

Sine

Random

Shock

Static load

Micro vibration

Acoustic

Specimen length [mm]:

800.0

Specimen width/dia [mm]:

800.0

Specimen height/thk [mm]:

800.0

Mass max. [kg]:

50.0

Frequency min. [Hz]:

100.0

Frequency max. [Hz]:

4000

Acceleration shock [g]:

5000

Data acquisition:

16 Chanel

Cleanroom classes (ISO 14644-1):

ISO Class ≤5

ISO Class 6

ISO Class 7

ISO Class 8

ISO Class 9

Certification:

ISO/IEC 17025

ISO 9001

AS/EN/JISQ 9100

Keywords:

shock pyroshock, astrofein