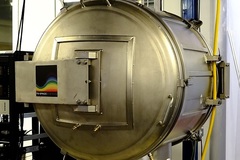

Vacuum Oven to reduce the outgassing values on optical subassemblies and components

before the assembly.

Heat is applied to release impurities and other contaminants, from components in a closed system (vacuum chamber), while a vacuum pump removes those impurities

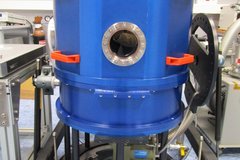

Features thermal:

Vacuum

Solar simulator

Thermal plate

Temperature controlled shroud

Specimen length [mm]:

489.0

Specimen width/dia [mm]:

495.0

Specimen height/thk [mm]:

529.0

Mass max. [kg]:

20.0

Higher temperature [K]:

473.0

Lower temperature [K]:

298.0

Vacuum limit [hPa] [mbar]:

10-5mbar

Project heritage:

FCI&IRS Telescope Optics for MTG Satellite Series: Optical Mounts and Environmental Test Campaign

Cleanroom classes (ISO 14644-1):

ISO Class ≤5

ISO Class 6

ISO Class 7

ISO Class 8

ISO Class 9

Certification:

ISO/IEC 17025

ISO 9001

AS/EN/JISQ 9100

Keywords:

Bake-out, outgassing, vacuum, contaminants, oven, Lidax