You need to analyse and size a spacecraft structure, a payload structure, electronic box, propulsion system? We have done this all before hundreds of times, benefit from our experience in projects such as:

- BIOMASS

- Orion ESM

- ExoMars

- Metop-SG

- SGEO/EDRS-C/H2-Sat

- PRISMA

- ACLS rack for the ISS

- and so many others

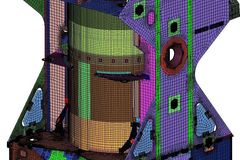

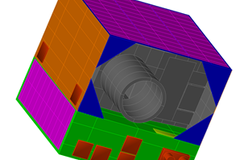

We use the Finite Element Method (FEM) to describe the behaviour of a structure from early conceptual phases up to the final sizing in addition to analytical methods and classical hand calculation. Space Structures uses NASTRAN, ANSYS® and and ABAQUS® for state-of-the-art solver technology together with HyperWorks or Femap as pre- and post-processing tool.

Other methods include vibro-acoustic analysis, fatigue & fracture mechanics. We simulate all materials including composites.

For CAD design we use state-of-the-art software suites such as CATIA® and SOLIDWORKS®

Finite Element Analysis (FEA)

- Modeling based on CAD design data

- Problem-adapted discretisation

- Statics (linear and nonlinear)

- Dynamics (modal analysis and vibration, incl. random- & micro-vibration)

- Strength verifications

- Deformation analyses

- Stability analyses (imperfection modeling where required)

- Thermo-elastic analyses (including temperature mapping)

- Shock Analyses (modal and transient)

- Model correlation with test data

- Model condensation (Guyan and Craig-Bampton)

- Optimisation

General structure analysis

- Analytical methods and classic hand-calculation

- Programming of tools for FEA pre- and postprocessing

- Vibro-acoustic analyses (BEM & FEM)

- Shock analyses according to ECSS-E-HB-32-25A (we are co-authors of that HB)

- Bolt verifications according to ECSS-E-HB-32-23A, VDI 2230, DIN 18800, EN 1993-1-8

- Insert design according to ECSS-E-HB-32-22A

- Fatigue verifications according to ESAFATIG, EN 1993-1-9

- Fracture mechanics analyses with ESACRACK, NASGRO

Design engineering

- 2D and 3D CAD model building

- Parametric models

- Multibody simulations (pure kinematic and dynamic)

- Consideration of all relevant manufacturing constraints and boundary conditions

- All relevant drawings including manufacturing drawings

Materials

- Metals, including special alloys (INVAR, etc.)

- Composites (CFRP, GFRP, PCB, metal-ceramics, etc.)

- Special Materials (glas, tethers, concrete, ...)