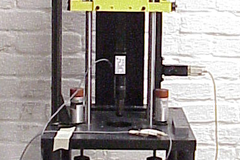

We have developed a dust erosion test bench delivering movables and seal manufacturers with accurate and reliable results @RT or LT.

The test equipment is intended to provide results simulating impacts of solid microparticles occurring during flights. The IVC (detailed visual inspection) and IMI (microscopic inspection) and the measurement of mass loss are performed for damage characterization.

The tribometry bench used at the SONACA Test Center is using an instrumented precision micro-sander and the ASTM G76-95 standard allowing comparative tests on flat coupons or seal samples.

The test machine is calibrated to erode samples with the following characteristics:

o Impacting flow rate: 0.6 to 0.8 gr/sec

o Particle size: 0.080 to 0.150 mm

o Impactor: Corundum (grade ABC 120)

o Temperature : @RT or @ low temperature (-55 °C+/-3°) regulated

o Incidence angle: from 15° to 90° by step of 15 °.

Our erosion testing department performs tests on:

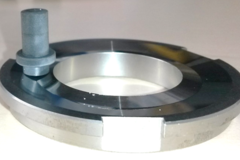

o PTFE, rubber or butyl seals

o Composite panels

o Coated, uncoated, painted or polished skins

o Sealants

o All other types of surfaces

We deliver test results simulating:

o Dust erosion in the atmosphere