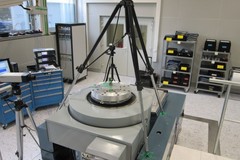

The NLR Avionics Division operates a laboratory for vibration and shock tests. These tests can be done in accordance with any applicable standard including the RTCA DO-160F, MIL-STD-810F and IEC standards. Also dedicated test procedures can be applied. The VST laboratory is included in the Dutch Accredition Counsil (RvA) register of test laboratories under no. L220, for areas described in detail in the accreditation.

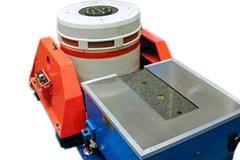

The VST-lab has three vibration test systems available. The two larger shakers (V810, V875) are used for general purpose vibration and shock tests, the smaller shaker is especially suited for small items that have to be tested for a high level/high frequency environment (e.g. turbojet engine components). A sine vibration level of 60 g for a 3 kg load is feasible up to 5 kHz.

Speccifications below: V875LS

Features mechanical:

Sine

Random

Shock

Static load

Micro vibration

Acoustic

Specimen length [mm]:

750.0

Specimen width/dia [mm]:

750.0

Mass max. [kg]:

600.0

Frequency min. [Hz]:

1.0

Frequency max. [Hz]:

2100

Acceleration sine max. [g]:

112.0

Acceleration random max. [g rms]:

56.0

Acceleration shock [g]:

112

Data acquisition:

Siemens SCADAS III/LMS Mobile, max 24 channels

Force sine max. [kN]:

35.6

Force random max. [kN rms]:

26.6

Displacement max. [peak to peak mm]:

69.85

Project heritage:

--

Cleanroom classes (ISO 14644-1):

ISO Class ≤5

ISO Class 6

ISO Class 7

ISO Class 8

ISO Class 9

Certification:

ISO/IEC 17025

ISO 9001

AS/EN/JISQ 9100

Keywords:

NLR