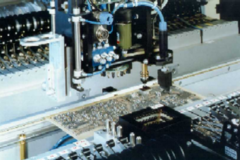

X-Ray radiography is the most commonly applied non-destructive imaging method for the analysis of EEE components. It is an essential step during destructive physical, construction and failure analysis. Furthermore, it is included as a final production test in a multitude of screening flows. Often, for a component batch to attain Class 1 quality level in both the ESA and MIL standard system , a 100% radiography screening is indispensable. The Tesat EEE labs are equipped with state-of-the-art, micro focus, real-time x-ray equipment to test your components in accordance with the following applicable methods:

• ESCC 20900

• MIL-STD-750, method 2076

• MIL-STD-883, method 2012

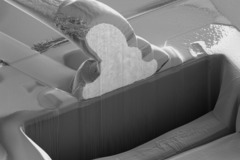

Our equipment is also capable of performing 3D X-ray or computer tomography (CT) scans. Through computerized processing of a multitude of individual x-ray exposures under different angles, a three-dimensional data set is compiled which can be rendered into arbitrary cross-sectional images or illustrative 3D views. This tool has proven to be very helpful in complex construction and failure analyses.

We are able to offer detailed analyses of individual components as well as (up-)screening tests on complete component batches containing up to hundreds of specimens. We are fully equipped for the analysis of ESD sensitive devices.