Coldwelding (or “contact-welding”, “adhesion”, “stiction”) is a solid-state welding process in which joining takes place without fusion/heating at the interface of the two parts. Coldwelding is likely to occur in metal-metal contacts in vacuum. This can lead to failure of space mechanism, which are typically stored compact while launch and are unfolded for their mission in orbit.

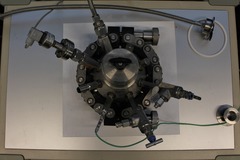

AAC’s test-facilities enable the measurement of the adhesion force between two materials in cyclic closed contacts which are subjected to fretting. This means that pin and disc are oscillated in their contact plane with small amplitudes (50 μm). "Cyclic contact" means that the contact between the pin and the disc is closed and opened for several (thousand) cycles.

Post-test analysis may cover measurement of wear by profilometry, state of coating, investigation of surface structure or material transfer by SEM/EDX.

AAC runs also a cold welding database based on the results of general validation studies.

Measurement of

• Adhesion force

• Friction force

• Load force

• Lateral amplitude

• Environmental Data

Different options are available (on demand)

• Testing from air to high vacuum – simulation of launch conditions

• Testing in controlled gas environment – e.g. simulating Martian atmosphere (6 mbar in CO2)

• Testing according to STM279

• long term vacuum

Aerospace & Advanced Composites GmbH - your highly experienced partner in material testing and development for space, aerospace and terrestrial applications.